Introduction: The beverage landscape has been undergoing a seismic shift with a marked increase in the demand for Ready-To-Drink (RTD) cocktails. This global trend has taken the beverage industry by storm, offering consumers the convenience of a bar-quality cocktail experience straight from the bottle, anytime, anywhere. The RTD Boom: The explosion of the RTD market can be attributed to several factors. Changing lifestyles, evolving taste preferences, and an increased focus on convenience have all played significant roles. However, one factor stands out in particular: the growing consumer demand for natural ingredients. Nature at the Forefront: More and more consumers are turning their backs on artificially flavored beverages. Instead, they’re seeking out drinks that boast all-natural ingredient lists, and RTD cocktails are answering this call. Premium RTD brands like Bali Water are leading the way, creating cocktails that use only the finest natural ingredients to deliver unique, vibrant flavours that captivate the palate. Bali Water: A Pioneering RTD Brand: At Bali Water, we’ve always believed in the power and purity of nature. That’s why our RTD vodka beverages are crafted from natural fruit juices, lightly carbonated spring water, and rice vodka. The result? A range of delightful beverages that tantalize the taste buds while staying true to our commitment to all-natural ingredients. The Future of RTDs: The future of the RTD market looks promising, with industry forecasts predicting steady growth in the years ahead. As the trend towards natural ingredients continues to grow, we can expect to see even more innovative RTDs that deliver delicious, natural flavours in convenient, ready-to-drink formats. In an ever-changing beverage landscape, RTD cocktails are proving that nature and convenience can coexist, serving up delightful drinks that are as easy to enjoy as they are satisfying. Conclusion: In a world where consumers are increasingly concerned with what they put in their bodies, the rise of RTDs reflects a broader movement towards natural, quality ingredients. Brands like Bali Water are at the forefront of this trend, ensuring that consumers don’t have to compromise between convenience, taste, and a commitment to nature. Discover the world of natural, ready-to-drink cocktails today with Bali Water, and taste the difference that nature makes.

Author Archives: Chris Bowes

Indonesian President Joko “Jokowi” Widodo stated that he will bring a number of essential agendas to the 2024 World Water Forum which is slated to be held in Bali. Indonesia is appointed to host the 10th forum. “I’d like to assert several important agendas that must be prioritized, such as efforts of water conservation, clean water supply and sanitation, food and energy resilience, as well as natural disaster mitigation such as floods and drought,” said the President when meeting with the president of the World Water Council Loic Fauchon at Jakarta State Palace, Wednesday, February 15, 2023. He said the agendas must be joint works by involving the public and various elements. He also said dialogues and partnerships between countries are necessary for the people’s welfare. Additionally, Jokowi underlined that Indonesia needs many innovations, especially financial innovations by involving the government and private parties, technological innovations in managing energy and food consumption, as well as the commitment of all parties to share and work together. “I truly hope that this initial meeting ahead of the 10th WWF could result in important agendas that we will follow up in the peak event of the 10th WWF in Bali on May 18-24, 2023,” the state head remarked. Today, February 15, President Jokowi welcomed the visit of Loic Fauchon and delegations of the World Water Forum at Jakarta State Palace.

Bali’s northern Regency of Buleleng is working on expanding the export potential of fruit produced in the region. One of the fruits exported from northern Bali is the mangosteen – known locally as manggis. The current production of mangosteens in the Buleleng Regency approaches 10.5 tons. Local farmers are accessing export markets via an agent operating from Denpasar. To increase production, the Buleleng Regency Administration plans to dedicate 50 hectares of land in Busungbiu District to mangosteen cultivation. The Head of Agriculture and Horticulture in Buleleng, I Gede Subudi, said farmers would get assistance from the Regency, including 100 seedlings per hectare for the Kaligesing variety of Mangosteen, two tons of organic fertilizer per hectare, 300 kilograms of dolomite fertilizer per hectare, and a further 100 kilograms of NPK fertilizer per hectare. The assistance will be given to farmers in each village starting from June 2023 to allow the land area to be gradually prepared for planting.

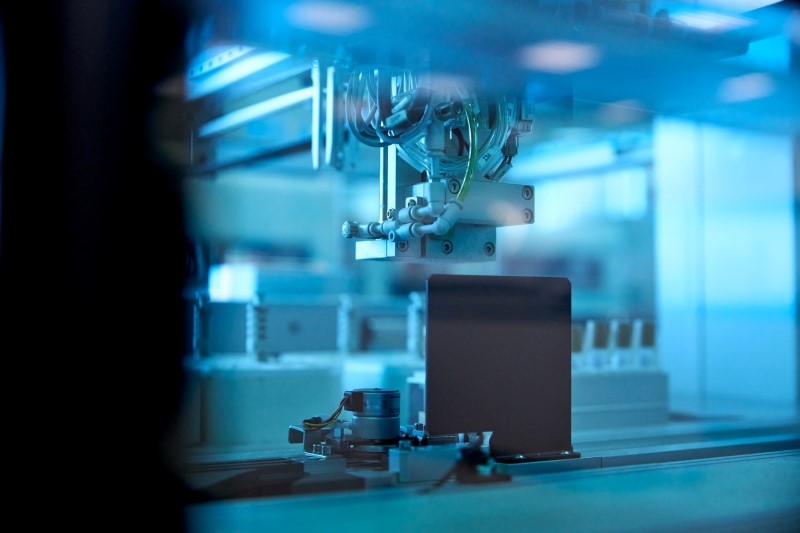

In food and beverage manufacture, the method plays an integral role in the whole manufacturing process. If the technique is not a proper match for the entire production flow, the final products may not succeed. Today, our topic is flash pasteurization – a process that applies heat to destroy pathogens in food and beverage products. Flash pasteurization is one of the technologies used by Bali Water to create our beverages. Let’s take a quick look at how the flash pasteurization method work and its influence on the beverage industry. What is flash pasteurization? Flash pasteurization – a process that applies heat to destroy pathogens in beverage products Flash Pasteurization called a form of High Temperature, Short Time (HTST) pasteurization that has gained popularity in recent times. This method heats the milk between 72°C to 74°C for 15 to 20 seconds with targets resistant pathogenic bacterial spores (Clostridium botulinum spores) Flash pasteurization treats foods and liquids at high temperatures for a short period to slow microbial growth. Advances in beverage processing technology have perfected the procedure to maintain the original taste and quality of products. This method is named after scientist Louis Pasteur when he discovered when an alcohol manufacturer commissioned him to determine germ theory of fermentation – a fine line between wine and vinegar. How flash pasteurization (HTST) works Flash pasteurization is a complicated process Flash pasteurization for each type of product has different processing. Here we provide an example of a standard milk pasteurization system as a material reference. Balance the tank: maintain a constant heat for the incoming milk Milk feed pump: creates suitable pressure for efficient flow. Flow control system: make sure that a sufficient amount of fluid is in the conduits at any time. Filters and clarifiers: remove dirty elements from the products Homogenizer: reparate fat globules into micro globules to avoid fat separation in standing milk PHE with recreation, heating and cooling sections: facilitates efficient pasteurization Flow diversion valves: make sure that all the conditions and equipment for the pasteurization process have been met before the milk comes through. Instrumentation and control equipment: raises system efficiency and reliability Peripheral utilities like steam compressed air and water income: Provides the required utilities for heating, cooling, and pressurized procedure. Conduits or piping system: Facilitate the flow of milk and utilities from one step to the next without the intrude of contamination. Advantages and disadvantages of flash pasteurization? Benefits Flash pasteurization is especially beneficial to maintain the natural flavor, color, and nutritional compounding of liquid products such as fruit juices and milk. This method can further expand the shelf life of products compared to the traditional pasteurization method. For instance, flash pasteurized milk has a refrigerated shelf life of two or three weeks. A study published in “Frontiers in Bioscience” reported that the flash pasteurization process was ideal for retaining the nutritional quality of human breast milk compared to other methods. The United States Department of Agriculture tightly regulates pasteurization methods to ensure the safety of the products being made. Drawbacks Flash pasteurization is famous for its expensive process than the traditional method because of the technology and advanced equipment involved. There is also some evidence that the high temperatures involved in the process can destroy or alter the activity of beneficial compounds in liquid products, such as certain immunoglobulins in breast milk, as reported in the “Journal of Perinatology.” Flash pasteurization could also kill some non-pathogenic beneficial microbes. These health problems are what have led many to consume unpasteurized products instead. However, there is a hidden danger of contamination in consuming these pasteurized products if stored for even a short amount of time. Distinguish Flash pasteurization with other Processings Aseptic/Extended shelf life (ESL) filling Similar to hot filling, aseptic filling sterilizes the liquid by heat before being filled. But the packaging is sterilized separately, allowing the liquid to be supplied at a lower temperature. The Aseptic filling requires close coordination and complex interactions between personnel, sterilized product, filling equipment, and cleanroom practices to guarantee a sanitary product. Many packaging styles allow for pouches and juice boxes that cannot be tunnel pasteurized or hot-filled. Beverage products can potentially be labeled as “natural”, which must fulfill standard requirements. Disadvantages The equipment and personnel require significant investment. Limited packaging manufacturers have this capability. High-Pressure Processing High-Pressure Processing (HPP) does not use heat to preserve. Instead, this process applies a large amount of pressure to keep the product. The product is held in a flexible container and put into a high-pressure chamber that uses about 87,000 pounds/square inch (PSI) for 3 to 5 minutes. Advantages Maintains original taste, color, and nutrition ingredients better than heat pasteurization methods, giving better “fresh-like” characteristics It does not require heat to kill some micros. Meets clean label requirements to ensure the quality control Disadvantages We do not have many suitable packaging options. Reduce the production processing time, leading to longer production times and higher costs. Pasteurizer equipment The pasteurizer is equipped with all the required equipment to complete control of the working flows and a storage tank for the pasteurizer good, made of AISI 304 stainless steel and internally as well as externally polished. The stainless steel electrical panel suggests an operator panel that helps verify and set all the control machine parameters and an electronic chart recorder that stores the values of all the variables controlling the phases of pasteurization. The flow-fixed pasteurization unit for fruit juices from 3000 l/h is different. The pasteurizer is equipped with four tubular heat exchangers (for each specific section) with a length of 6 meters each. It’s made of stainless steel AISI 304 for the parts in contact with water and AISI 316L stainless steel for details in touch with the product. In conclusion To wrap up, pasteurization process is a optimal method to heat every particle of milk or milk product. With the purpose is extend the shelf life of beverage products and maintain the original taste, flash pasteurization is such an innovative invention in the beverage manufacturing. Bali Water uses this technology as part of our process to create the true #VacationInACan